Our direct presence in MotoGp and Superbike allows us to better understand and suit the needs of working professionals.

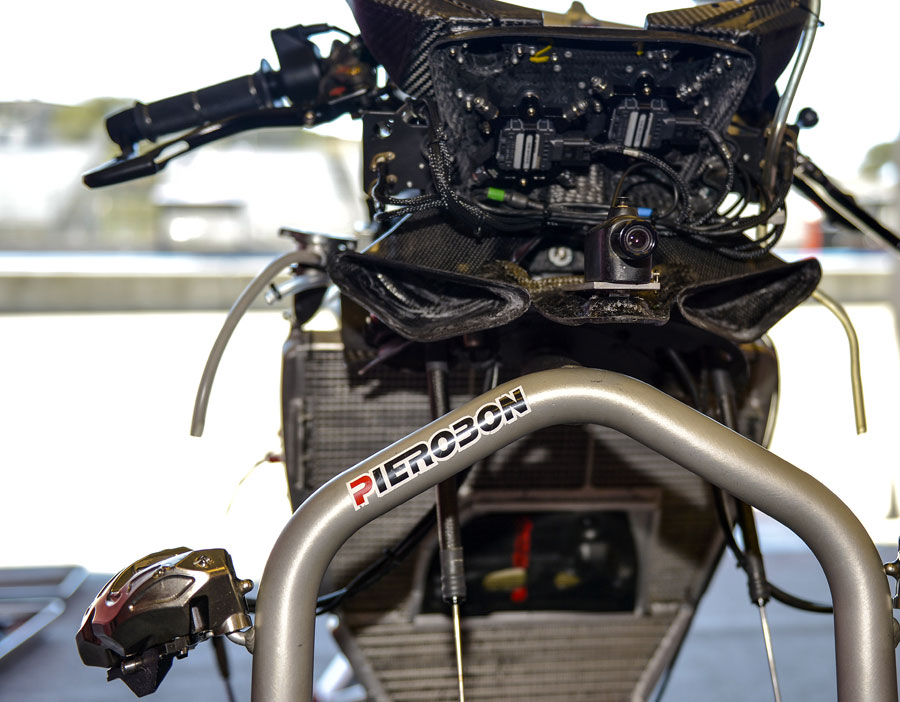

In this respect, the front stand has been designed and developed for use at racetrack with the objective of facilitating the maintenance and replacement work of the motorcycle frontend components.

Its special shape, based on a patent filed, facilitates the fitting and removal of the front wheel.

The stand is made in a special aluminium alloy, purposely realized on our specific techniques.

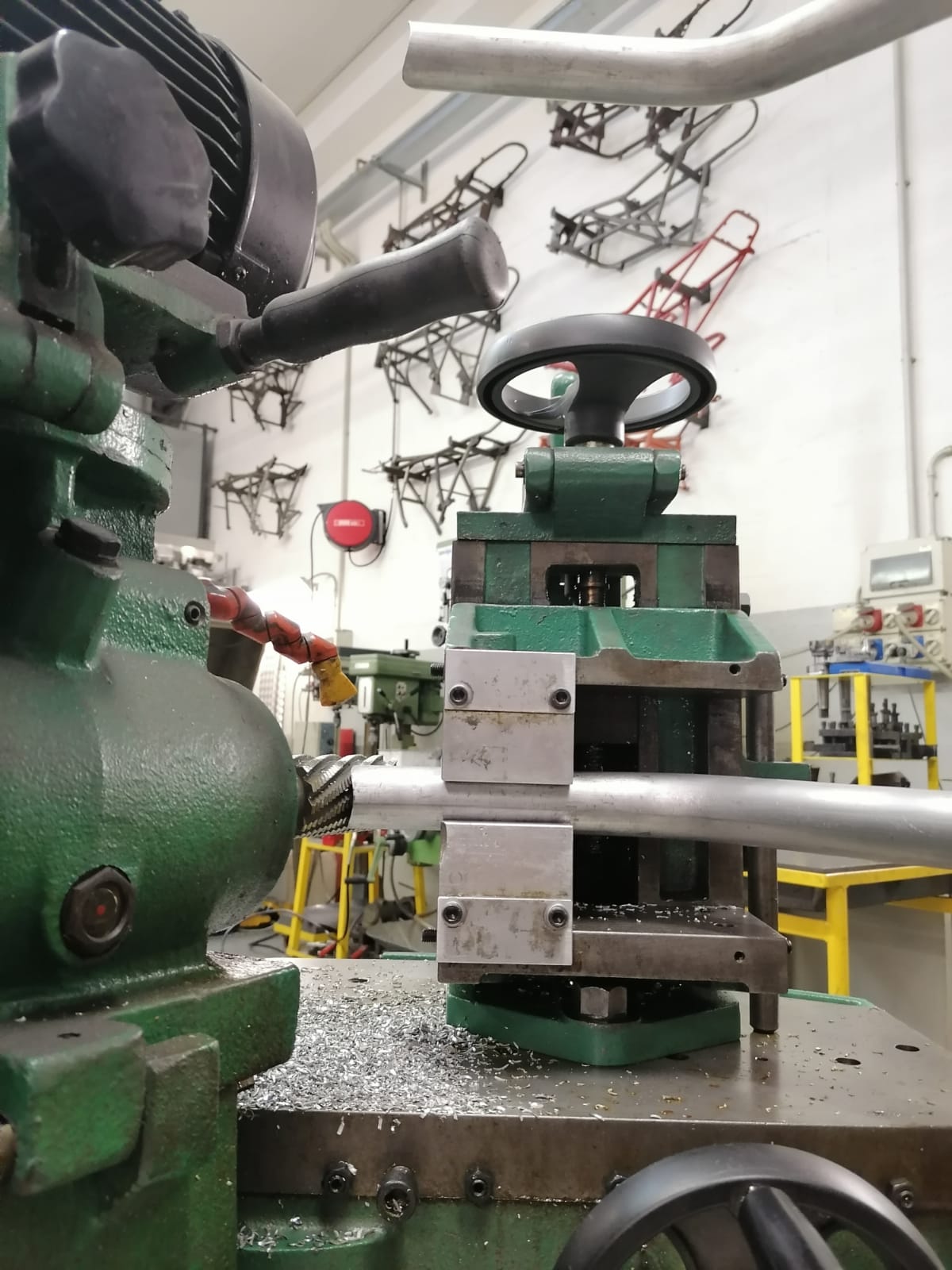

The tube is appropriately cut and, before the curving, requires a specific heat treatment.

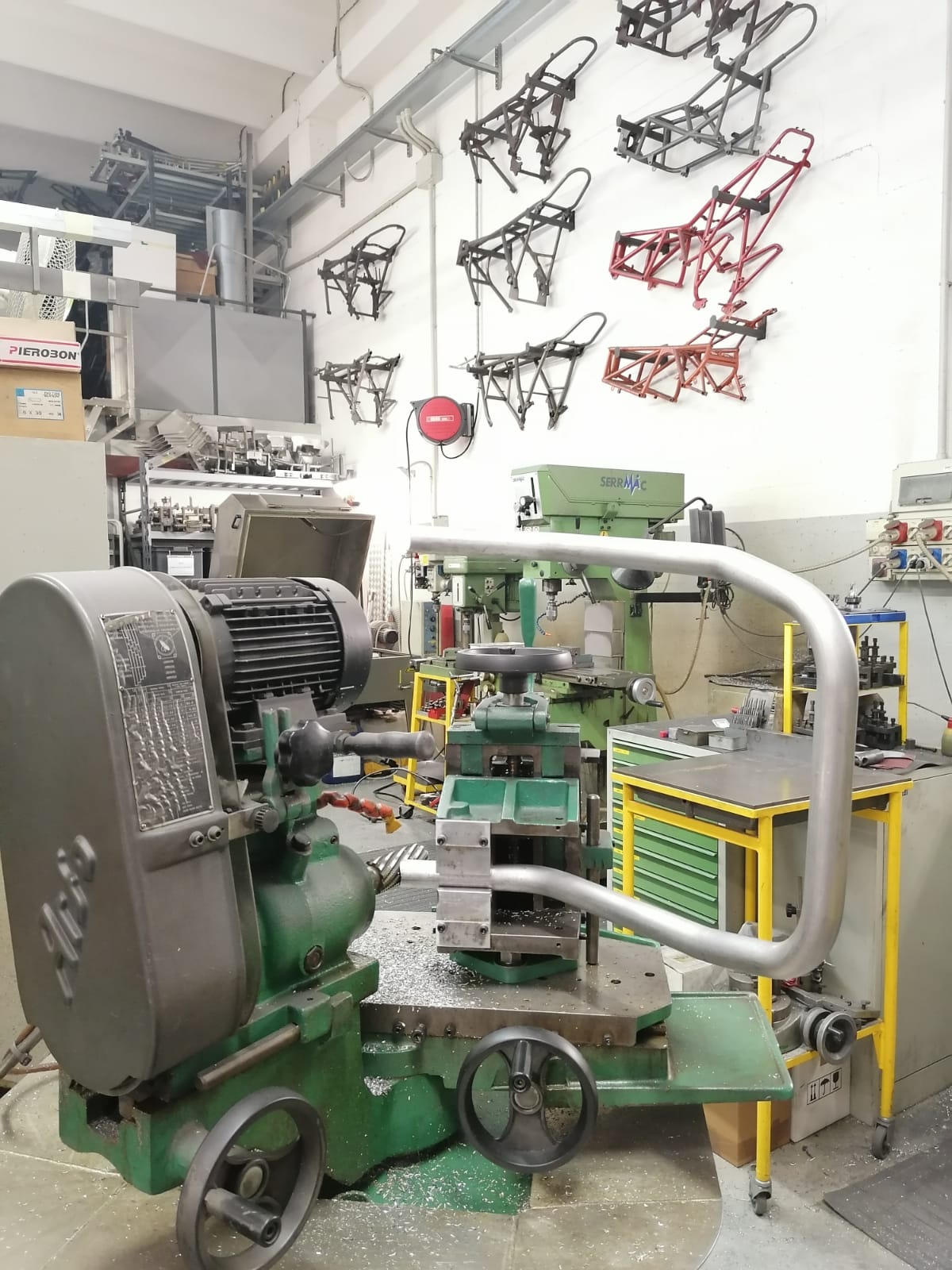

The tube bending is an important step. This process is always supervised by one of our technicians.

Once this phase had been completed, we proceed with the tubing adaptment that is realized by hand with the use of a milling machine.

At the same time we proceed with the forming of the wheel support metal sheets and with the realization of the CNC billet components as pin holder and pivoting pieces.

Each stand is clearly marked.

Once ready, each component is mounted on its welding jig.

The jigs are two: one for the bottom and one for top part of the stand.

Each subpart is completely weld inside the jig.

Furthermore, on the bottom part of the stand we weld three supports: two laterally situated for hold the front calipers and one on the bottom side to hold the front wheel axle when they are dismounted from the motorcycle.