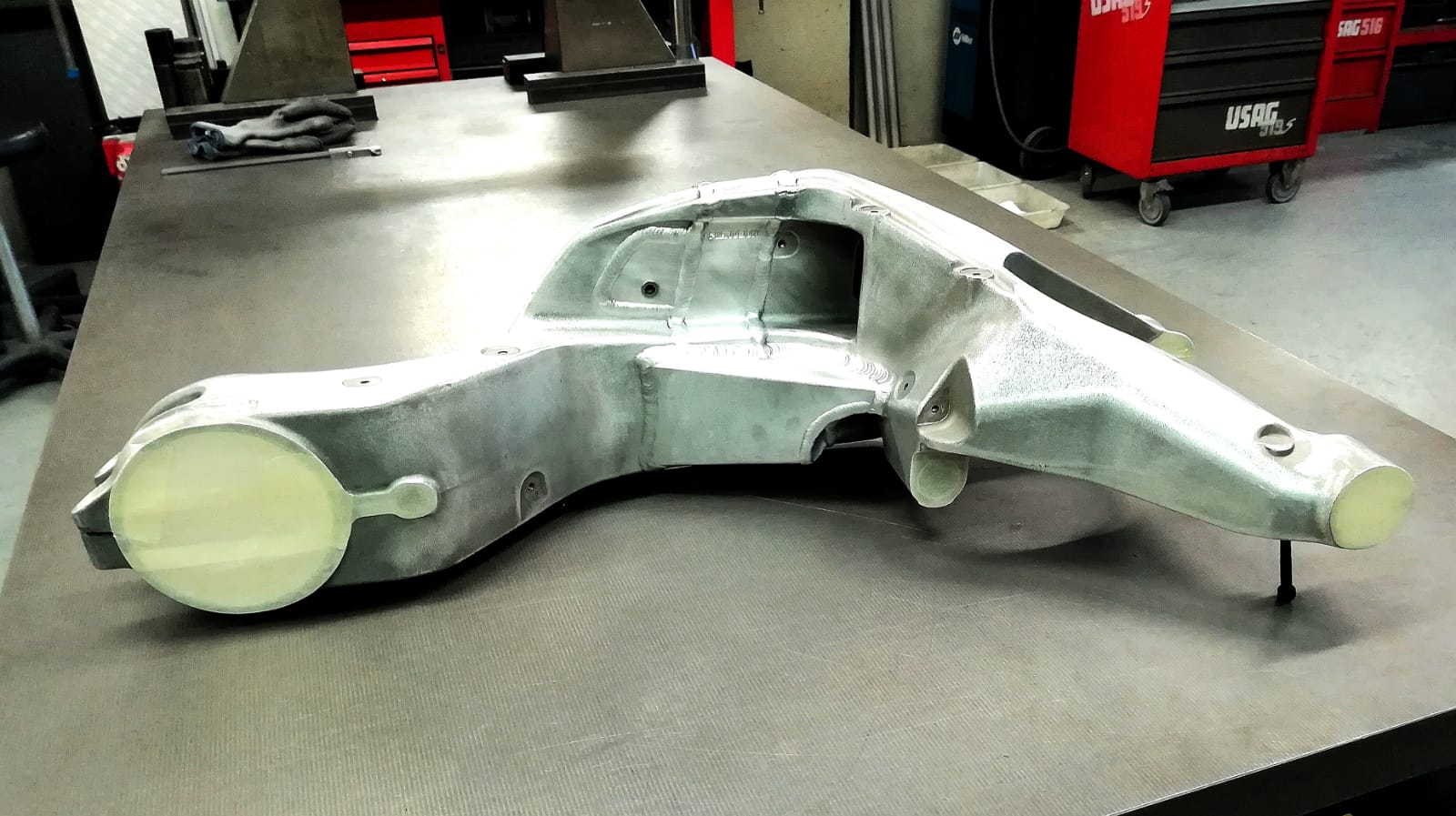

This swingarm upgrade arises from the need to ensure more stability of the motorcycle during acceleration and braking and gives more secure feeling in exiting the corner.

To achieve the objective, we decided to add a machined extenction to the swingarm, to obtain a total lengh major of 35 mm respect the original quotation.

The swingarm is stripped and cutted.

The remaining parts are cnc worked allowing the housing of the extenction billet part on both ends of the swingarm.

We realize the components that we will weld to the swingarm: the extension part machined from billet and the reinforcement sheet metals.

The swingarm is all welded inside at the welding jig.

After having finished the welding, a certain cooling time in temperature-controlled which depends on several factors, has to be respected, before remove it from the jig.

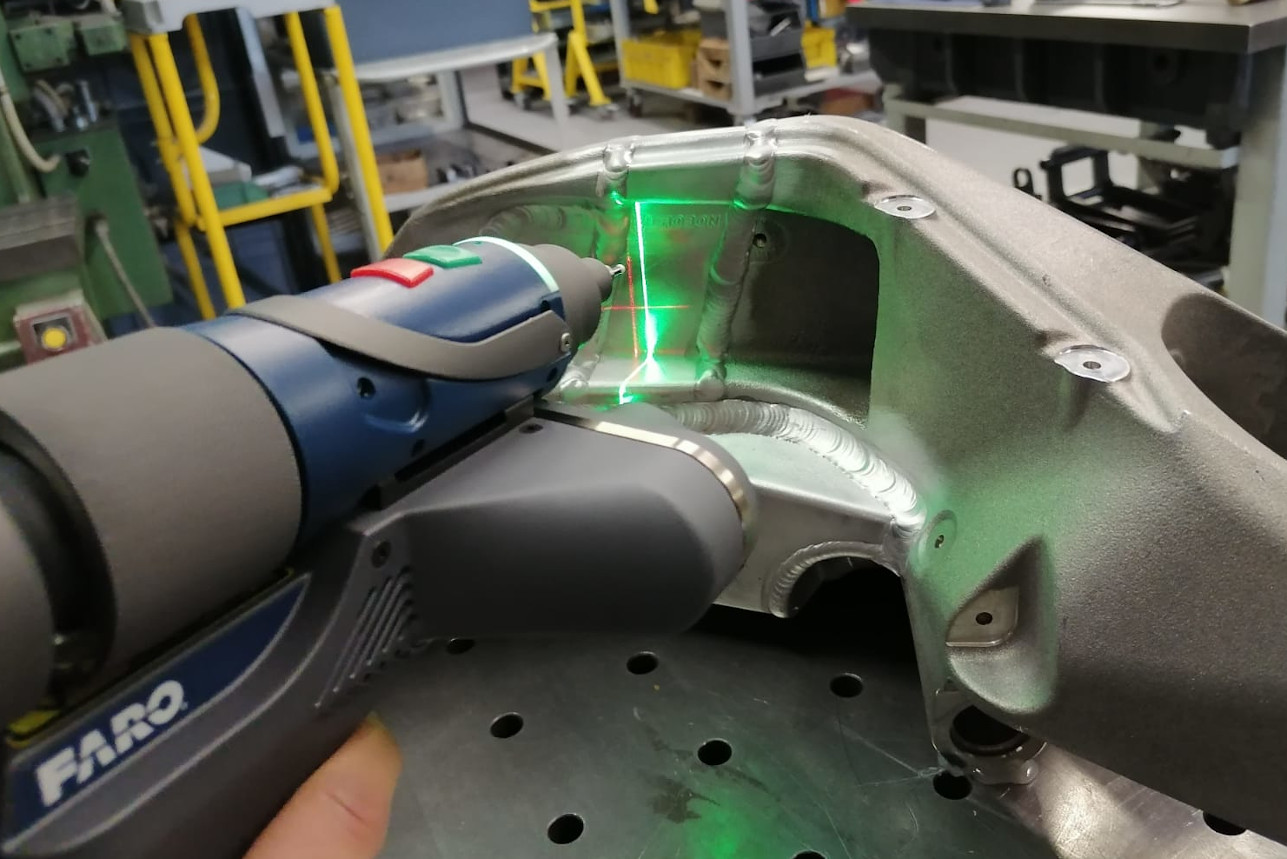

After an accurated inspection with penetrating liquids to check that there’re no defects on the welding, we proceed with dimensional control through the aid of CAM2® ScanArm, with 3D scanning laser and tactile measurement.

Now it’s ready for the painting. However, before we need to protect it.